Alloy Boiler pipe and tube standard and specification

It takes an uncompromising level of quality to manufacture pressure tubing and piping. AGICO understands the critical end-use applications and maintains the strictest production standards and procedures required to meet the precise ASTM/ASME specifications required for heat ex-changers, condensers and boilers. We offer complete, non-destructive testing equipment to ensure our products consistently meet our customer’s specifications and worldwide quality standards.

Boiler tubes is tubes used for boiler systems, like boilers for civil use in life, general industrial boilers, locomotive boilers and thermal power boiler. According to different steam pressure, thermal power boilers are divided to low, medium, high pressure, high pressure, sub-critical pressure, super-critical pressure boilers, ultra-supercritical units.

| Steel grade | Tensile strength (Mpa) | Yield strength (Mpa) | Elongation (%) | Impact energy(J) | Hardness | Standard | ||

| Rockwell Hardness | Brinell Hardness | |||||||

| WT<5.1mm | WT≥5.1mm | |||||||

| <15mm | ≥15mm | |||||||

| St35.8 | 360-480 | 235 | 225 | 25 | - | - | - | DIN17175 |

| Sr45.8 | 410-530 | 255 | 245 | 21 | - | - | - | |

| 15Mo3 | 450-600 | 270 | 22 | - | - | - | ||

| 13CrMo44 | 440-590 | 290 | 22 | - | - | - | ||

| 10CrMo910 | 450-600 | 280 | 20 | - | - | - | ||

| 14MoV63 | 460-610 | 320 | 20 | 55 | - | |||

| 12Cr1MoV | 470-640 | 255 | 245 | 21 | 41 | - | - | |

| <15mm | ≥15mm | |||||||

| SA192 | ≥325 | 180 | 35 | - | 77HRB | 137HB | ASMESA192 | |

| SA106-B | ≥415 | 240 | - | - | - | ASMESA106 | ||

| SA106-C | ≥485 | 275 | - | - | - | |||

| SA556-C2 | ≥480 | 280 | - | - | ASMESA556 | |||

| SA210-A1 | ≥415 | 255 | - | 79HRB(143HB) | ASMESA210 | |||

| SA210-C | ≥485 | 275 | - | 89HRB(179HB) | ||||

| SA209-T1a | ≥415 | 220 | - | 81HRB | 153HB | ASMESA209 | ||

| SA213-T12 | ≥415 | 205 | - | 163HB(85HRB) | ASMESA213 | |||

| SA213-T22 | ≥415 | 205 | - | 163HB(85HRB) | ||||

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo | V |

| GB3087 | 10 | 0.07~0.13 | 0.17~0.37 | 0.35~0.65 | ≤0.030 | ≤0.030 | ≤0.15 | - | - |

| 20 | 0.17~0.23 | 0.17~0.37 | 0.35~0.65 | ≤0.030 | ≤0.030 | ≤0.25 | - | - | |

| GB5310 | 20G | 0.17~0.24 | 0.17~0.37 | 0.35~0.65 | ≤0.030 | ≤0.030 | - | - | - |

| 20MnG | 0.17~0.25 | 0.17~0.37 | 0.70~1.00 | ≤0.030 | ≤0.030 | - | - | - | |

| 25MnG | 0.22~0.30 | 0.17~0.37 | 0.70~1.00 | ≤0.030 | ≤0.030 | - | - | - | |

| 15CrMo | 0.12~0.18 | 0.17~0.37 | 0.40~1.70 | ≤0.030 | ≤0.030 | 0.80~1.10 | 0.40~0.55 | - | |

| 12Cr2MoG | 0.08~0.15 | ≤0.50 | 0.40~1.70 | ≤0.030 | ≤0.030 | 2.00~2.50 | 0.90~1.20 | - | |

| 12Cr1MoG | 0.08~0.15 | 0.17~0.37 | 0.40~1.70 | ≤0.030 | ≤0.030 | 0.90~1.20 | 0.25~0.35 | 0.15~0.30 | |

| ASME SA106 | SA106 B | ≦0.30 | ≧0.1 | 0.29~1.06 | ≦0.035 | ≦0.035 | - | - | - |

| SA106 C | ≦0.35 | ≧0.1 | 0.29~1.06 | ≦0.035 | ≦0.035 | - | - | - | |

| ASME SA333 | SA333 Ⅰ | ≦0.30 | ≧0.1 | 0.40~1.06 | ≦0.025 | ≦0.025 | - | - | - |

| SA333 Ⅵ | ≦0.30 | ≧0.1 | 0.29~1.06 | ≦0.025 | ≦0.025 | - | - | - | |

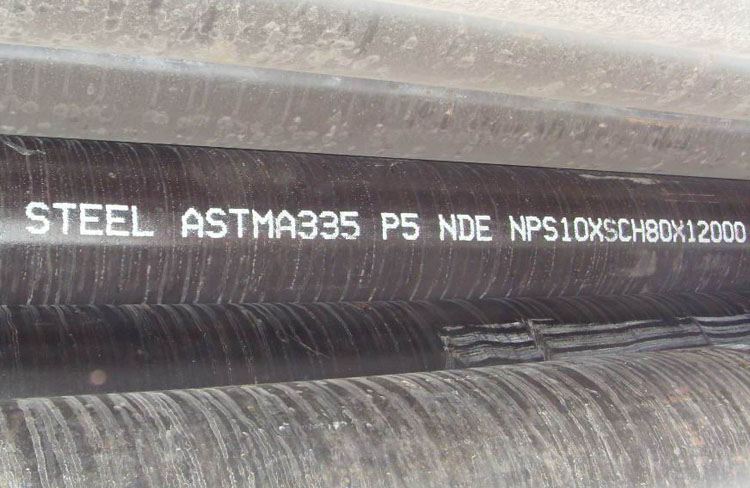

| ASME SA335 | SA335 P11 | 0.05~0.15 | 0.50~1.0 | 0.30~0.60 | ≦0.025 | ≦0.025 | 1.00~1.50 | 0.44~0.65 | - |

| SA335 P12 | 0.05~0.15 | ≤0.50 | 0.30~0.61 | ≦0.025 | ≦0.025 | 0.80~1.25 | 0.44~0.65 | - | |

| SA335 P22 | 0.05~0.15 | ≤0.50 | 0.30~0.60 | ≦0.025 | ≦0.025 | 1.90~2.60 | 0.87~1.13 | - | |

| SA335 P5 | ≦0.15 | ≤0.50 | 0.30~0.60 | ≦0.025 | ≦0.025 | 4.00~6.00 | 0.45~0.65 | - | |

| DIN17175 | ST45.8/Ⅲ | ≦0.21 | 0.10~0.35 | 0.40~1.20 | ≦0.040 | ≦0.040 | - | - | - |

| 15Mo3 | 0.12~0.20 | 0.10~0.35 | 0.40~0.80 | ≦0.035 | ≦0.035 | - | 0.25~0.35 | - | |

| 13CrMo44 | 0.10~0.18 | 0.10~0.35 | 0.40~0.70 | ≦0.035 | ≦0.035 | 0.70~1.10 | 0.45~0.65 | - | |

| 10CrMo910 | 0.08~0.15 | ≦0.50 | 0.40~0.70 | ≦0.035 | ≦0.035 | 2.00~2.50 | 0.90~1.20 | - | |

| ASME SA210 | SA210A-1 | ≦0.27 | ≧0.10 | ≦0.93 | ≦0.035 | ≦0.035 | - | - | - |

| SA210C | ≦0.35 | ≧0.10 | 0.29~1.06 | ≦0.035 | ≦0.035 | - | - | - | |

| ASME SA213 | SA213 T11 | 0.05~0.15 | 0.50~1.0 | 0.30~0.60 | ≦0.025 | ≦0.025 | 1.00~1.50 | 0.44~0.65 | - |

| SA213 T12 | 0.05~0.15 | ≦0.50 | 0.30~0.61 | ≦0.025 | ≦0.025 | 0.80~1.25 | 0.44~0.65 | - | |

| SA213 T22 | 0.05~0.15 | ≦0.50 | 0.30~0.60 | ≦0.025 | ≦0.025 | 1.90~2.60 | 0.87~1.13 | - | |

| ASME SA192M | SA192 | 0.06~0.18 | ≦0.25 | 0.27~0.63 | ≦0.035 | ≦0.035 | - | - | - |

| JIS G3461 | STB340 | ≦0.18 | ≦0.35 | 0.30~0.60 | ≦0.035 | ≦0.035 | - | - | - |

| STB410 | ≦0.32 | ≦0.35 | 0.30~0.80 | ≦0.035 | ≦0.035 | - | - | - | |

| EN 10216-1 | P195TR1 | ≦0.13 | ≦0.35 | ≦0.70 | ≦0.025 | ≦0.020 | ≦0.3 | ≦0.08 | ≦0.02 |

| EN 10216-1 | P235TR2 | ≦0.16 | ≦0.35 | ≦1.20 | ≦0.025 | ≦0.020 | ≦0.3 | ≦0.08 | ≦0.02 |

| Note 1: EN Residual emlement Nb≦0.01%,Ti≦0.04%,Ni≦0.30%,Cu≦0.30%,total≦0.70% | |||||||||

| Note 2: Other grade can also be provided after consuliting with customers | |||||||||

- ASTM A209, T1,T1A, T1b

- ASTM A199,T4,T5,T9,T11,T21,T22,T91

- ASTM A213,T2, T5,T5b,T5c, T9, T11, T12, T17,T21,T22,T91,T92

- ASTM A334, Grade1,3,6,7,8,91,112.

- DIN17173, BS3603, JIS G3464, BS3606, JIS G3462, DIN17176, BS3604

- ASME SA 333: SA333 Grade1, SA333 Grade 6

- ASME SA335: SA335 P11, SA335 P12, SA335 P22, SA335 P5, SA335 P1, SA335 P9,

- DIN 17175: St45.8, 15Mo3, 16Mo3, 13CrMo44, 10CrMo910, 14MoV6-3, X10CrMoVNb9-1 = T91 / P91

- JIS G3461: STB 340, STB 410

- EN 10216-1: P195 TR1, P235 TR2

- ASME SA 106: SA 106B, SA 106C10, 20, 20G, 20MnG, 25MnG, 15CrMoG, 12Cr2MoG, 12Cr1MoVG, 10Cr9Mo1VNb, SA106B, SA106C

- SA210A1, SA210C

- SA333 I, SA333 VI

- SA335 P5, SA335 P11, SA335 P12, SA335P22, SA335 P91, SA335 P92, 15NiCuMoNb5-6-4, 1Cr18Ni9 (TP304H, X6CrNi18-10), 1Cr19Ni11Nb (TP347H, X7CrNiNb18-10),TP321H, TP347HFG, CODE CASE 2328-1 (S30432), TP310HCbN, 20G, 12CrMoG, 15CrMoG, 12Cr1MoVG, 25MnG, 15MoG, 12Cr2MoG